2022/8/1/ · The paper discussed treatment for chicken manure which is produced in abundance compared to other poultry manure due to the high demand of

2021/11/12/ · This research aims to build a smart solar chicken manure fermentation system to control the conditions of chicken manure fermentation effectively, improve

2020/1/1/ · Mix 100 g dried grass particle (2–3 cm), 5 g (NH 4) 2 SO 4 and water in flask (moisture 65%, pH 6.8) and incubate at 30 °C for up to 42 days. Dry. Increase protein content and in vitro digestibility after fermentation; the fermented feed can be used to replace corn in the diet for broiler chickens. Broiler chicken.

This review article presented the current status and traditional agricultural waste (livestock manure and crop straws) utilization , the art of aerobic fermentation process

2018/5/1/ · 2.2. Estimation of the total manure productions and potential pollutants. We attempt to estimate the total pollutants productions and discharges in 2013 regarding COD, NH 3-N, total nitrogen (TN), total phosphorous (TP), by parameterizing the emission factors (EF).Although the year of 2013 cannot reflect the dynamic transformation of animal

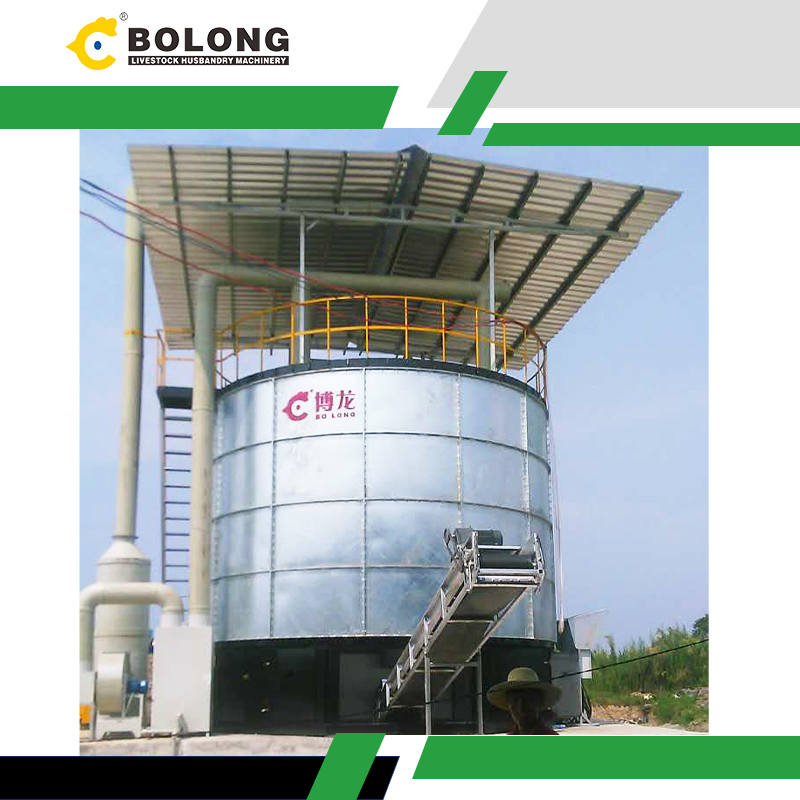

Features. High temperature fermentation by actinomycetes can greatly reduces odor. It kills fly eggs and weed seeds. High temperature processing of dead chicken. One unit (50m) can process 100,000 to 200,000 poultry manure. Very few breakdowns (thanks to the patented two-rotor system which is not a burden to the machine)

2023/11/29/ · way to deal with excessive poultry manure. Since 1984, a series of regulations on poultry manure emissions have been introduced [21]. The United States and Germany, among others, also have manure management laws. In some developing countries, anaerobic fermentation technology started late and was developed slowly.

The first option——To make chicken manure waste compost. Two types of high-efficiency composting equipment: Organic Fertilizer Fermentation Tank and Compost Turner. Organic Fertilizer Fermentation Tank:. Output: 3~4.5 m³/day. Power Supply: 380V50Hz. Treatment capacity: 7~10 m³/day.

Accepted 13 June, 2013. This study aimed to determine bio-ethanol potential of poultry manure The manure was hydrolyzed by. dilute H SO (0.2, 0.4, 0.6, 0.8 and 1 M) at temperature of 100 and 130

1984/7/1/ · An investigation was conducted for 15 months to assess the potential for methane production from high solids slurries consisting of manure from laying chickens combined with 0, 20, 40, and 60% by volatile solids (VS) weight chopped wheat straw. Two pilot scale digesters, each with an operating volume of 100 liters, were fed on alternate …

2021/5/1/ · The first is a manual method that can convert 10 tonnes of poultry manure per day (Xiao et al. 2018b). This model relies on manual labor to pre-treat the manure, feed it to the larvae, and harvest the resulting larvae and fertilizer. The second method is mechanized and is suitable for medium-sized enterprises.

2024/6/1/ · Anaerobic batch fermentation was conducted with TS concentrations ranging from 2.5 % to 20 %: 2.5 %, 5 % and 7.5 % for wet-AD; 10 % and 15 % for semi …