Various advanced technologies have been utilized to treat the livestock and poultry manure, and wastewater in the breeding industry in recent years. This study aims to

Min. Order FOB Price; 1 Set: US$144,880.00-154,330.00: Port: Shanghai, China: Production Capacity: 300: Payment Terms: Contact Now Inquiry Basket

Specialize in Organic Fertilizer Production. ABC Machinery is a leading manufacturer of organic fertilizer production with CE & ISO certifications. We specializes in the design, development, and production of large-scale equipment such as fermentation tanks, and fertilizer granulators. ABC machinery provide customized solution for organic

The content of undigested crude protein in animal manure is very high, the content of protein in air-dried chicken manure is 24–30%, in pig manure is 3.5–4.1%, and in cow manure is 1.7–2.3% . In the face of the severe contradiction between supply and demand of protein feed, livestock manure is a potential feed resource.

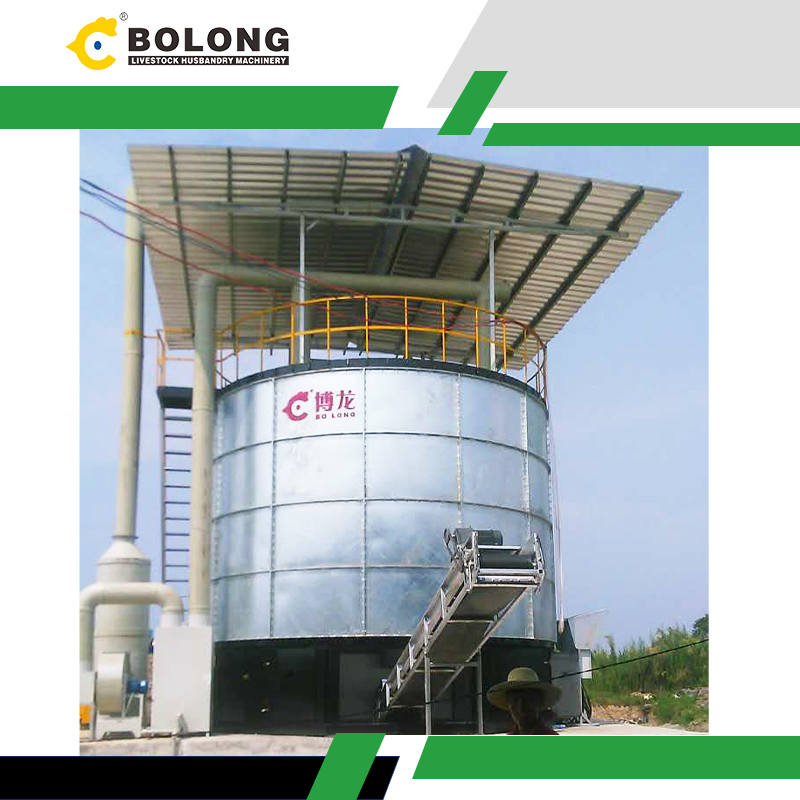

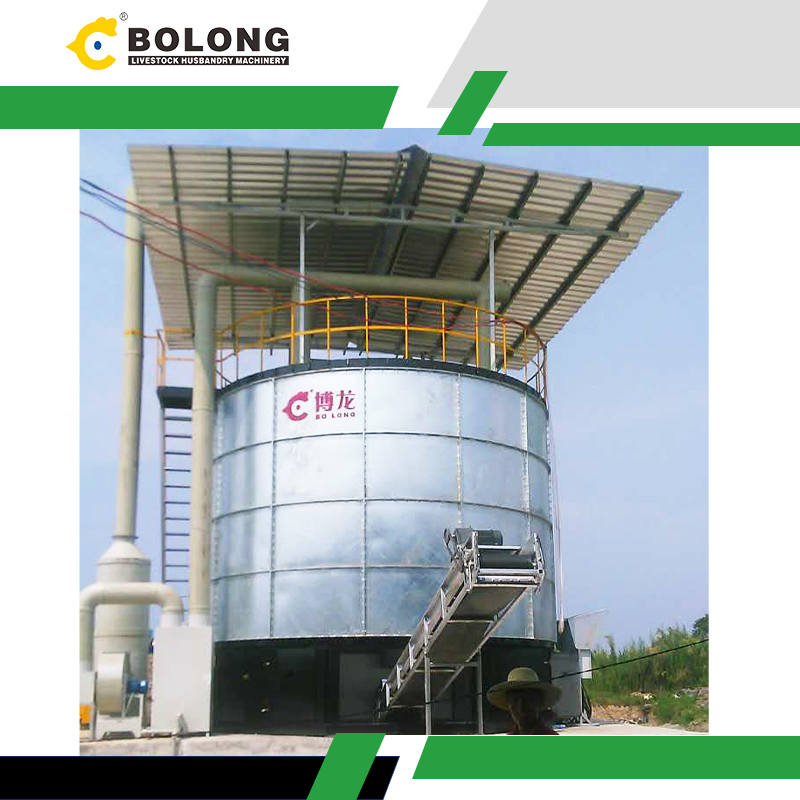

1. Closed Fermenter: The tank is fully enclosed, meeting industrial production standards, preventing gas leakage, and eliminating secondary pollution.. 2. Thermal insulation treatment: The tank uses polyurethane insulation, ensuring year-round fermentation, regardless of external conditions.. 3. Energy Efficiency: A patented heat exchange system

December 11, 2023. News. Livestock and poultry manure drying and fermentation machines are specialized integrated equipment for handling organic waste such as livestock and poultry manure, domestic sludge, and kitchen scraps. The primary purpose is to utilize the activity of microorganisms to biologically decompose and mature organic matter in

Company Introduction: Zhejiang Mingjia Environmental Protection Technology Co., Ltd is located in Haiyan huangqiao industrial zone of Jiaxing city, Zhejiang province, near Shanghai and Ningbo. Company is covering an area of more than twenty-thousand square meters with modern standard factories. We are committed to livestock breeding of waste

2023/12/15/ · With the increase in the number of livestock and poultry in farming, the issue of manure pollution has become increasingly severe. Failing to address this problem in a timely and proper manner can have serious environmental consequences. Therefore, using manure treatment equipment is a reasonable choice for dealing with this series of

There are four treatment procedure of the organic fertilizer fermentation tank. Firstly,automatically feeding.Then,you can make material get perfect stage through high-temperature fermentation. After that,material is discharged from your fermenter. Finally,you can put these fermented material into storage. organic tertilizer production tank.

2017/11/28/ · Livestock and poultry breeding industry is one of the main economic pillars of northeastern China. However, the amount of pollutants produced is much higher than that in other parts of China. Through a questionnaire survey, indoor experiment, and outdoor experiment, it was found that the resource utilization rate of livestock and poultry

2021/1/19/ · Dwindling fossil fuels, and the rise in energy demand have urged us to explore alternative renewable energy forms. An integrated process of dark fermentation and microalgal cultivation to deliver biofuels are gaining momentum in recent times. In this study, in the first stage, the starchy wastewater (SWW) with poultry manure (PM) was treated

2024/4/1/ · If these livestock manure and urine are not properly treated and rationally used, the pollutants will have a huge negative impact on the ecological environment and restrict the development of livestock and poultry industry. Co-fermentation is an attractive technology to improve VFAs production by treatment of solid organic wastes [23].

As a new generation equipment in the organic fertilizer industry, the rapid fermentation tank has changed the traditional pool fermentation process, greatly improving production efficiency, and taking the production of organic fertilizer products to a higher level.