2023/7/21/ · The Chinese standard document “Technical Specification for Harmless Treatment of Livestock and Poultry Manure” (GB/T 36195-2018) stipulates that solid livestock and poultry manure treatment must be maintained at a high temperature for no less than 7 days.

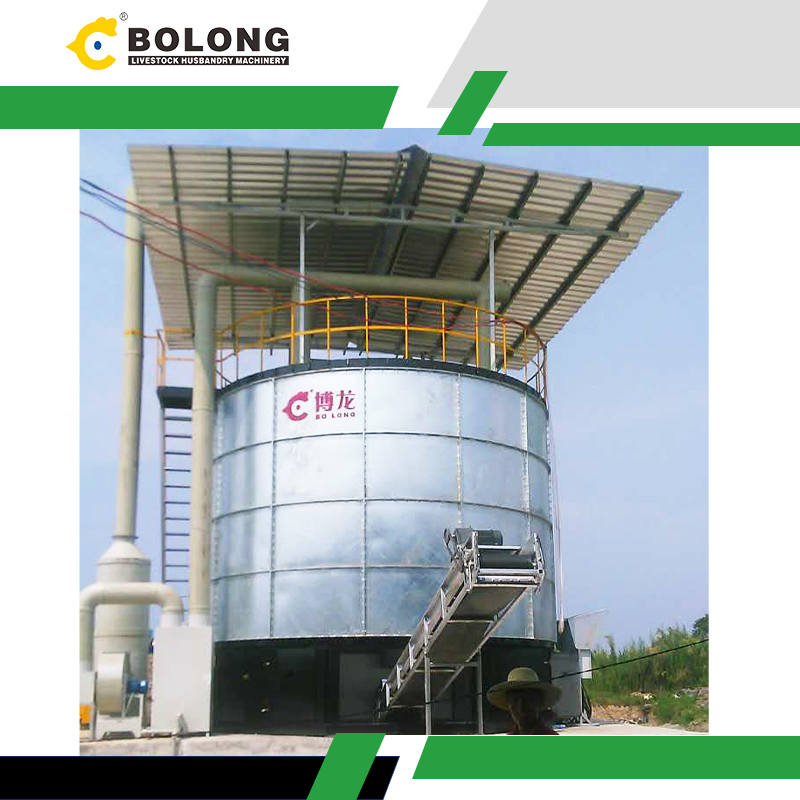

Manure Fermentation Tank Model:11FFG-116Total height:Dia 5600mm Height10050mm(Equipped with a rain shelter)Equipment weight:30TCover an area:40m2Effective volume:100m³Daily processing capacity:10-12m³/dayDaily output:3-4m³/hPower supply:380V 50HZTotal power:54.5KWOperating power:Around 27KW

Manure fermentation is a biological process that occurs under anaerobic conditions, which means in the absence of oxygen. The process involves the breakdown of organic matter by microorganisms into simpler compounds, mainly biogas, which is a mixture of methane and carbon dioxide. The fermentation process can be divided into four main stages

We provide. Packaging And Transport. Quality Test Before Delivery. Check Items When Packing. After-sale Service. The livestock and poultry manure fermentation tank can process animal manure and animal carcasses such as chickens, pigs, cattle, sheep, and horses. Its processing capacity is 2~5 cubic meters per day. Free inquiry now!

The High-temperature aerobic fermentation tank equipment developed by ABC Machinery adopts a fully enclosed design. The fecal fermentation process is not affected by the natural environment, allowing the production of organic fertilizer to meet industrial production standards, preventing the leakage of waste gas generated by fermentation, and

Entered the livestock equipment industry in 2014,integration production with marketing .“Deep Cultivating product ”is our Philosophy ——Refine one single product .Since 2013, we have manufactured three products : manure removal systems, fermentation tanks, and stainless steel troughs trough introduction and R&D.We will insist of doing correct

2023/7/27/ · 2.1.1. Design of Cattle Manure Fermentation Tank Based on Target Compost Amount In the operation of cow dung composting equipment, the design of inlet and outlet is very important. This paper believes cow dung import and export should be based on the fermentation tank’s structural size and target compost amount. The

2023/7/27/ · The national standard document “Technical Specification for Harmless Treatment of Livestock and Poultry Manure” specifies requirements for solid livestock and poultry manure treatment: the pile temperature must be maintained above 50 °C for no

Organic manure vertical fermentation tank designed by FPC company with 100-200m³ processing capacity. Manure fermentaion finished in 7days. FPC vertical type manure fermentation tank is an advanced organic fertilizer production machine. It can complete organic waste crushing, mixing and fermentation automatically.

2021/3/16/ · This review article presented the current status and traditional agricultural waste (livestock manure and crop straws) utilization , the art of aerobic fermentation process including ultrahigh temperature fermentation and composting.

effective volume of the fermentation tank was 4.5 L. Batch anaerobic fermentation was conducted at (5±2)°C for 20 d using 70% raw materials and 30% inoculations. Two-phase anaerobic fermentation experiment was carried out at medium temperature of (35±2)°C . The TS of SL was 6.6%, the HRT of the acidogenic

2024/4/1/ · All fermentation bottles were settled in an incubator for 16 days. About 20 mL mixture of sludge and chicken manure was extracted from the fermenter every two days to determine various indexes (determination items: pH, ORP, NH 4 +-N, PO 3--P, SCOD, protein, polysaccharide, VFAs). The reactor was adjusted to a stable state when all

The manure fermentation equipment developed by Gemco Energy adopts totally closed design, the manure fermentation process is not affected by the natural environment, so that the organic fertilizer production meets the industrial production standards, prevents the waste gas generated by the fermentation from leaking, and eliminates secondary

The Weight Proportion of manure and Auxiliary material is about 5 to 10 :1. Confirm the proportion, then could get good compost. 2. Put the raw materials in fermentation tank by Fork-lift truck, height at least 1meter. Spread the mixed leaven in materials evenly. 2.2.2 Fermentation steps. 1.