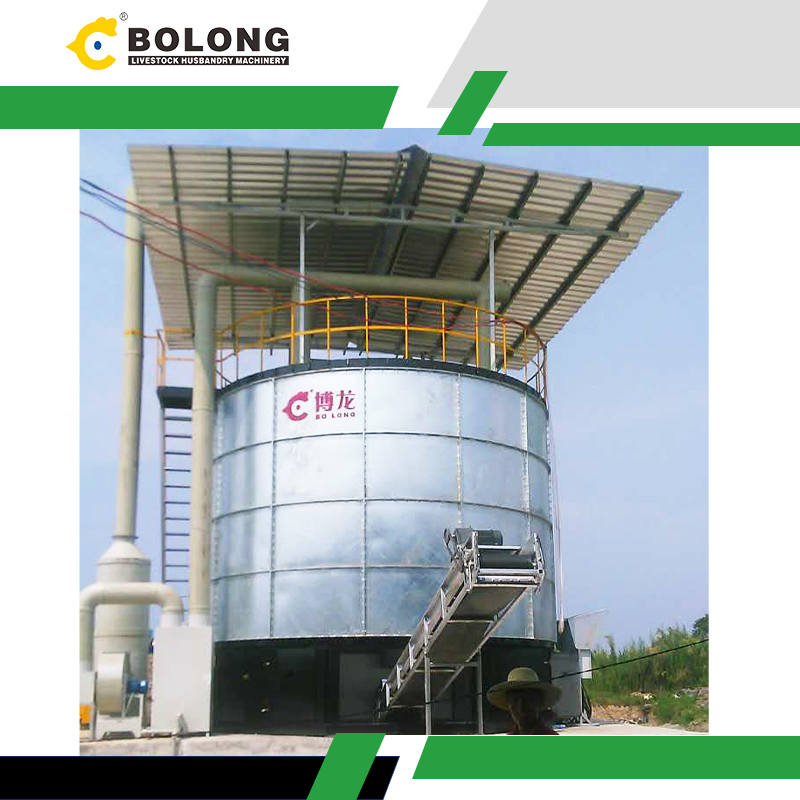

We provide. Packaging And Transport. Quality Test Before Delivery. Check Items When Packing. After-sale Service. The livestock and poultry manure fermentation tank can process animal manure and animal carcasses such as chickens, pigs, cattle, sheep, and horses. Its processing capacity is 2~5 cubic meters per day. Free inquiry now!

2023/10/1/ · Several factors affect animal manure emissions [4], including changes in the number of animals kept, changes in feeding cycles, differences in excretion coefficients, types of animal (e.g. pigs, cattle, chickens, geese), and farming (e.g. conventional, organic, or farm scale).. Feeding cycles and excretion coefficients have a significant

2024/6/1/ · Treating chicken manure (CM) through anaerobic digestion encounters a hurdle due to its high nitrogen content, leading to volatile fatty acid accumulation and

2024/6/1/ · Average daily biogas production from poultry manure at psychrophilic, mesophilic, and thermophilic conditions for pH range 6–8 and C/N ratio 40/1–10/1. The

375 kg poultry manure blend (50 kg manure+325 kg water) was filled to the tank and the processes done. Then the biogas production rates was evaluated and compared for two processes. Results showed that daily 6.33 m3 and 0.83 m3 biogas productions were obtained from fermentation of bovine animal manure and poultry animal manure.

2023/5/2/ · Anaerobic digestion of animal manure results in the production of renewable energy (biogas) and nutrient-rich biofertilizer. A further benefit of the technology is decreased greenhouse gas emissions that otherwise occur during manure storage. Since animal manure makes anaerobic digestion cost-efficient and further advance the

2024/3/5/ · The increase in the number of households in the regions of Uzbekistan poses new challenges in the energy supply of residential buildings [1, 2], the list of which includes biogas, coolants [3–5], batteries [], and phase transition materials [].Biogas is a renewable energy source that consists mainly of CH 4 (55–70%) and CO 2 (25–45%),

2013/6/1/ · A 12 L mesophilic CSTR of chicken manure fermentation was operated for 400 days to evaluate process stability, inhibition occurrence and the recovery behavior suffering TAN concentrations from 2000 mg/L to 16,000 mg/L.A biogas production of 0.35–0.4 L/gVS in and a COD conversion of 68% were achieved when TAN concentration

2017/3/25/ · Water extraction of raw chicken manure elevated the carbon-to-nitrogen ratio 2.7-fold, i.e. from 7.48 to 19.81. The treated chicken manure (T-CM) thus became suitable for biogas fermentation as

2023/12/15/ · Vertical Fermentation Tank: Based on the nature of the solid phase in the rapid fermentation tank of organic fertilizer, chicken manure fermentation can be divided into two . One method is to use crops (such as bran, soybean cake, etc.) as a substrate for fermenting chicken manure. These substrates not only make up the solid

2024/4/1/ · The co-fermentation of sludge and chicken manure increased the production of VFAs. • Acetic acid accounted for the main proportion of VFAs production. • Microbial characteristics were significantly different at acid and alkaline pH. • Alkaline pH enriched acidogenic bacteria and improved VFAs production. •

This equipment is an vertical and completely enclosed composting system which professionally manages chicken manure ,pig manure ,etc into high- quality organic fertilizer . The high-value organic fertilizer benefits to different plants and crops.Organic fertilizer is favorable to increase amount of soil organic matter and to improve soil

2018/6/4/ · This paper performs a batch experiment for pre-acidification treatment and methane production. from chicken manure by the two- stage anaerobic fermentation process. Results shows that the acetate