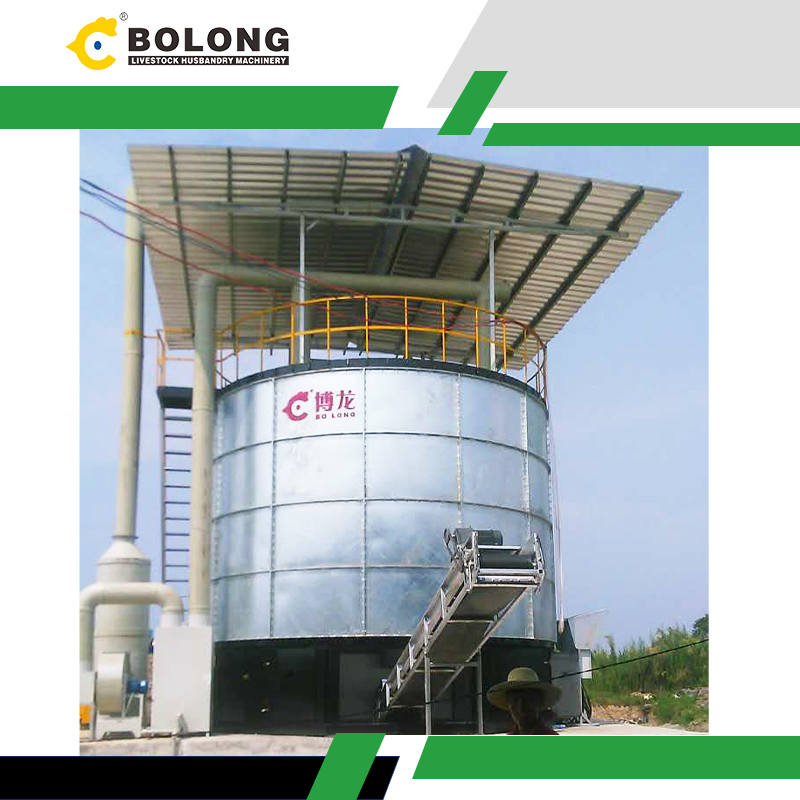

Considering its closed design and high automation, our In tank composting system has high efficiency in speeding up composting. Commonly, it takes about 20-25 days when your animal manure becomes good organic fertilizer powder, if you use compost turning machines to turn your compost. However, our fermentation tank makes it possible to

2019/1/24/ · Brewer’s spent grain (BSG) is a promising substrate for the production of biocontrol fertilizer (BF). The effects of temperature, water content and fermentation time on the conidiation and

Download Citation | On Aug 22, 2015, Yang Jiang and others published Rapid production of organic fertilizer by dynamic high-temperature aerobic fermentation (DHAF) of food waste | Find, read and

2024/1/19/ · Beer Fermentation Tank Sizes. Beer fermentation tanks cover a wide range of sizes from a few barrels to massive volumes over 1000 barrels. Some typical fermenter capacities include: Pilot Systems: 1-3 BBL; Microbreweries: 3-7 BBL, 7-30 BBL; Pub Breweries: 15-30 BBL; Production Breweries: 30-300 BBL, 600-800 BBL, 1000+ BBL

Whatsapp:+8618838168563. Add: Zhengzhou City, Henan Province. Explore Shop Home; Products. Fertilizer Fermentation Equipment. Movable Composting Machine

2.Increase the temperature to 90°C-100°C by electric heating, then turn off the power for 2 hours, and keep the temperature between 65°C and 80°C. At the same time, the matching stirring system in the fermentation tank stirs at intervals, and the whole fermentation process is completed. It can be produced and processed in about 10 hours.

Horizontal fermentation tank is suitable for large fertilizer production line. It has low price and Its output is 10-12m3/d. It also covers a small area. So, increase the biomass of all parts of the plant, and thus increase crop yields. It also improves the quality of products. However, if the charcoal-based fertilizer is not fermented in ...

Organic manure vertical fermentation tank designed by FPC company with 100-200m³ processing capacity. Manure fermentaion finished in 7days. FPC vertical type manure fermentation tank is an advanced organic fertilizer production machine. It can complete organic waste crushing, mixing and fermentation automatically.

The fermentation times are relatively short in fertiliser fermenters. In the conventional method, composting organic matter with a turner takes about 20 days. The first fermentation process in a manure fermentation tank will last about 7 days, after which the production of organic fertiliser can be carried out every day.

Horizontal fermentation tank working principle: 1) Collect livestock and poultry manure back from farms and straw, edible fungus dregs and other wastes from rural areas, air-dry and crush them. 2) According to the fixed formula ratio of livestock and poultry manure 70%, smoke end, straw 30% mixed to join the high-speed fermentation equipment

1. High-temperature aerobic fermentation and bio-bacteria technology using with low energy consumption. 2. Closed fermentation, biological deodorization equipment to achieve no secondary pollution. 3. The device body made of stainless special materials to reduce corrosion and long life in Fermentation Tank for Cow Manure. 4.

2023/7/24/ · Introduction. Commercial fermentation tanks play a vital role in various industries, facilitating the fermentation process of liquids or semi-solids to create a wide array of products. Whether you’re in the brewery, biotechnology, or food processing industry, having the right fermentation tank can significantly impact the quality and efficiency of

Beer fermentation is a crucial step in the brewing process that involves the conversion of glucose (sugar) in the wort to alcohol and carbon dioxide by yeast. This process is vital to