The term “fermentation” is derived from the latin verb “fervere ” (which means “to boil”) because of the boiling appearance due to the production of carbon dioxide bubbles observed during alcoholic fermentation. In industrial microbiology, the term refers to processes that produce microbial cells (cell biomass), metabolites, enzymes

May 1, 2024 · Furthermore, high-throughput screening and automation have accelerated the discovery and development of new fermentation-based products. Exploring the Versatility of Fermentation for Various

Jul 7, 2005 · To increase product yields and to ensure consistent product quality, key issues of industrial fermentations, process optimization and scale up are aimed at maintaining optimum and homogenous reaction conditions minimizing microbial stress exposure and enhancing metabolic accuracy. For each individual product, process and facility, suitable strategies have to be elaborated by a comprehensive

May 23, 2024 · Some bioreactors are designed for small scale fermenters and some for large scale industrial applications from the microbial cell (few mm3) to shake flask (100-1000 ml) to the laboratory-scale fermenter (1 – 50 L) to pilot level (0.3 – 10 m3) to plant scale (2 – 500 m3) for large volume).

Jun 1, 2018 · This is because fermentation is usually the costliest process step, both in terms of variable costs (raw materials and utilities) and capital investment. In addition, fermentation performance impacts the performance of all downstream unit operations and the amount/nature of process wastes. Fermentation is also a complex unit operation (Yang

Feb 6, 2012 · Much attention has been focused on the production of ethanol for transportation fuel by sugar fermentation; however, a multitude of industrially important products can be produced by fermentation. These products have uses not only as fuels, but also as feedstocks for manufacturing plastics, pharmaceuticals, and other consumer goods.

May 1, 2009 · This study isolated a novel erythritol-producing yeast strain, which is capable of growth at high osmolarity. Characteristics of the strain include asexual reproduction by multilateral budding, absence of extracellular starch-like compounds, and a negative Diazonium blue B color reaction. Phylogenetic analysis based on the 26S rDNA sequence and physiological analysis indicated that the strain

Dec 24, 2022 · There are various types of fermentation which occur at the industrial level such as ethanol fermentation and fermentation processes used to produce food and wine. The ability to utilize the fermentation process in anaerobic conditions is critical to organisms which demand ATP production by glycolysis.

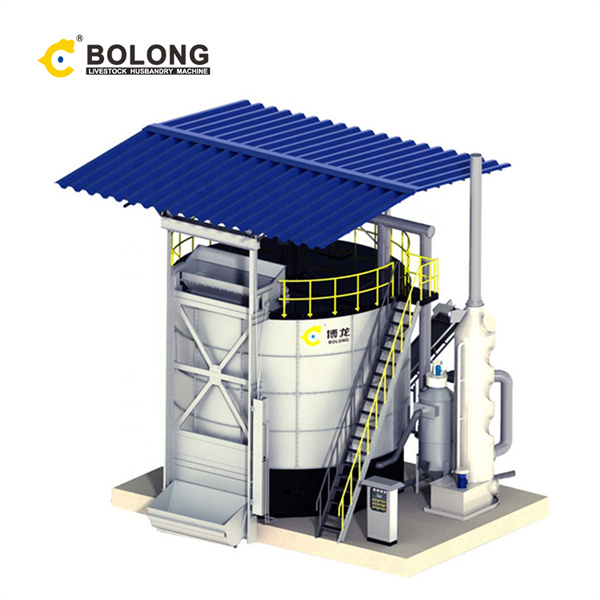

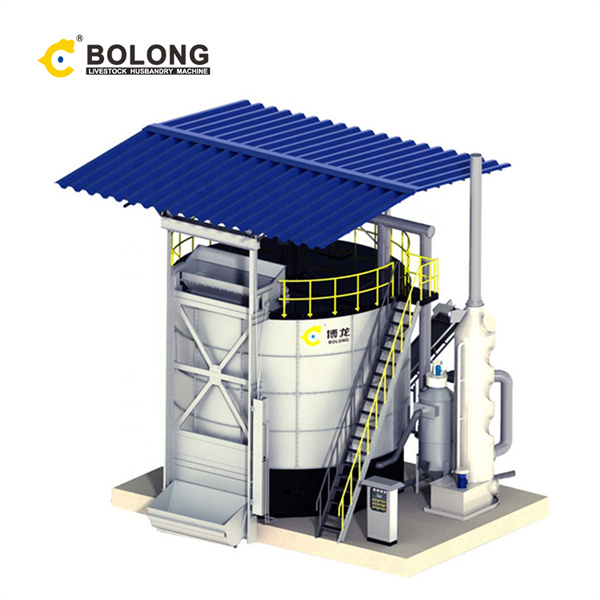

The fermenter design requires enhanced efficiency and authentication of the desired parameters with a high-quality product at a low cost. The fermenter’s strategy and mode of operation are focused on the output of microorganisms, the product’s cost, the condition required for the anticipated product development, and the scale of production.

Industrial fermentation is the intentional use of fermentation in manufacturing processes. In addition to the mass production of fermented foods and drinks, industrial fermentation has widespread applications in chemical industry. Commodity chemicals, such as acetic acid, citric acid, and ethanol are made by fermentation. [1]

Oct 8, 2015 · In industrial fermentation, companies regularly isolate pure colonies of high performance at the end of the fermentation to maintain the desired strain phenotype in subsequent fermentations.

Jun 23, 2012 · The simultaneous inoculum of yeasts and bacteria is a feasible solution for improving fermentation in wines with a harsh chemical composition, capable of inhibiting microbial activity. Considering the risk of wine spoilage due to lactic bacteria, co-inoculum is suggested in white wines with a low pH. However, climate change has also caused problems in achieving malolactic fermentation in red

Microbial fermentation processes have been manipulated by humans and are used extensively in the production of various foods and other commercial products, including pharmaceuticals. Microbial fermentation can also be useful for identifying microbes for diagnostic purposes.

Aug 11, 2023 · Fermentation optimization: Fermentation processes can be optimized to maximize the production of secondary metabolites. This includes optimizing the culture conditions such as temperature, pH, oxygen levels, and nutrient availability. Additionally, fed-batch or continuous fermentation strategies can be employed to enhance productivity.

Jun 1, 2018 · Scaling up industrial microbial processes for commercial production is a high-stakes endeavor, requiring time and investment often exceeding that for laboratory microbe and process development. Omissions, oversights and errors can be costly, even fatal to the program.