Basic Fermenter Design : External, Agitation & Aeration, Inlets and Outlets. De Becze and Liebmann (1944) used the first large scale (above 20 litre capacity) fermenter for the production of yeast. But it was during the First World War, a British scientist named Chain Weizmann (1914-1918) developed a fermenter for the production of acetone.

2024/1/1/ · Aside from agricultural waste products, there are crops grown solely for fuel generation, called energy crops. Species like maize, millet, and grass are commonly used for this purpose (Fig. 1).Agricultural waste is also the largest source of lignocellulosic biomass, constituting up to 40%–60% of livestock manure [9].Lignocellulose is a recalcitrant

2019/9/27/ · The global stainless steel fermenter market is expected to grow at a CAGR of 6.5% from 2022 to 2030. The market growth is attributed to the increasing demand for fermented food and beverages, and rising awareness about the benefits of fermented products in the healthcare and cosmetics industry.

2024/3/28/ · The Modular Bench-top Fermenter System market report provides a detailed analysis of global market size, regional and country-level market size, segmentation market growth, market share

Advantages when the tank outlet pipe is separated from the tank. Reduced extract losses due to more efficient product push outs and recovery. Best cleanability and CIP efficiency. Increased product quality – no product is left in the pipe

2023/8/3/ · Stirrer glands and bearings. The most important factor of designing a fermenter is to maintain aseptic conditions inside the vessel. It is highly challenging in the case of pilot-scale fermenters. Therefore stirrer shafts are required. These stirrer shafts play an important role to seal the openings of a bioreactor.

2018/1/1/ · The US ethanol plants primarily use corn as the feedstock, accounting for 95% of the total production while only 1% of the total bioethanol produced comes from food and beverage waste as shown in Fig. 5.3.In 2016, 38% of the total corn grown in the United States was utilized for ethanol production which is threefold higher compared to 12.4% in

2020/1/1/ · The global production of FV is increasing every year. In 2013, a 9.4% increase in FV production was recorded, compared to the 1.59 billion tons of FV in 2012. Besides that, the market size for FV in the United States has increased from US$71.4 billion in 2014 to US$104.7 billion in 2016 ( Grand View Research, 2018 ).

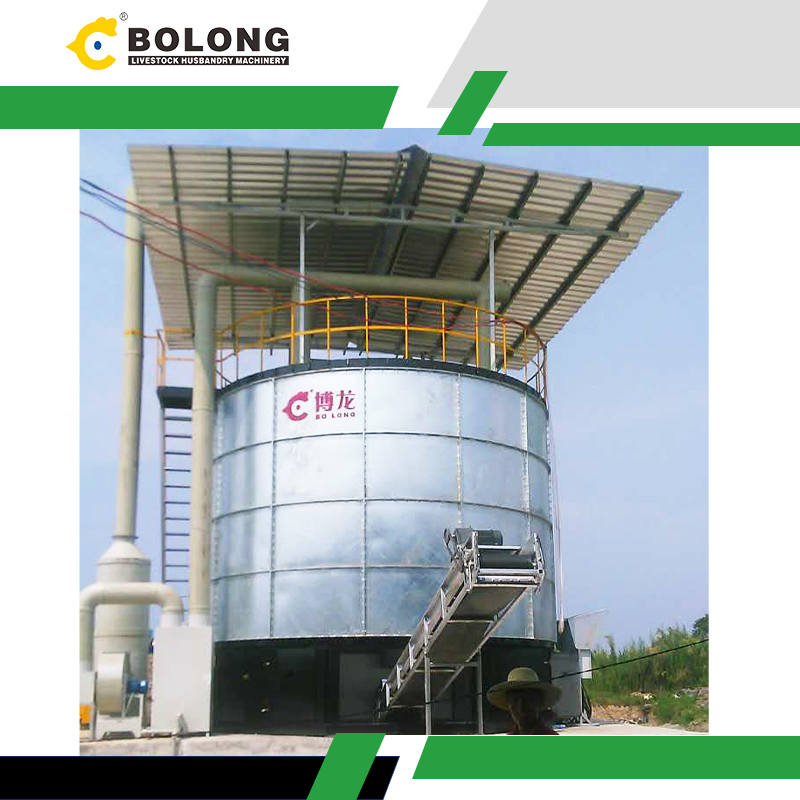

Due to the high demand for food and meat for the world's growing population, the agricultural sector is expanding every year. Timely and effective treatment is of utmost importance to utilize organic matter in agricultural waste and avoid environmental pollution. Composting or aerobic fermentation is an effective way to treat agricultural waste and produce organic

BrewIQ provides data on the pH, dissolved oxygen, gravity, conductivity, pressure, and temperature of your beer—giving brewers transparency at every step of the fermentation process to make better-informed decisions. The real-time data from BrewIQ aids real-time decisions, and if any complications arise during fermentation, adjustments can be

Published online 2021 Mar 26. doi: 10.3390/foods10040707. PMCID: PMC8066995. PMID: 33810435. Fermentation of Agri-Food Waste: A Promising Route for the Production of Aroma Compounds. Jasmine Hadj Saadoun, Gaia Bertani, Alessia Levante, Fabio Vezzosi, Annalisa Ricci, Valentina Bernini, * and Camilla Lazzi.

Solid animal manure, biowaste, and food waste are suitable for dry fermentation in a fermenter and occurs in the fermenter-boxes of bioreactors. Solid-state digesters are the name given to these systems. Methane is 25 times more potent than the greenhouse gas CO2, which is considered the main driver of global warming. Biogas being upgraded ...

2023/9/15/ · The effective conversion and recycling of organic solid waste contribute to the resolution of widespread issues such as global environmental pollution, energy scarcity and resource depletion. The anaerobic fermentation technology provides for the effective treatment of organic solid waste and the generation of various products.

1 天前 · The fermentation stage involves the addition of water, sugar, and nutrients required for microbial growth. Antifoam agents are also used to reduce the formation of foam that …