The content of undigested crude protein in animal manure is very high, the content of protein in air-dried chicken manure is 24–30%, in pig manure is 3.5–4.1%, and in cow manure is 1.7–2.3% . In the face of the severe contradiction between supply and demand of protein feed, livestock manure is a potential feed resource.

2022/1/5/ · Businesses that offer these for sale are likely specializing in the production of pellet based machinery. The ability to convert manure into pellets that are dry can only be done efficiently using these fertilizer machines. As you look at the newer fertilization fermentation tank structure, you will see that these are actually quite large.

2023/11/29/ · organic wastewater and poultry and livestock manure. The common treatment for livestock manure are composting and biogas engineering. They can be classified according to Table1. Aerobic fermentation has the advantages of a fast fermentation rate and rapid microbial proliferation. Anaerobic fermentation requires less

2013/6/1/ · A 12 L mesophilic CSTR of chicken manure fermentation was operated for 400 days to evaluate process stability, inhibition occurrence and the recovery behavior suffering TAN concentrations from 2000 mg/L to 16,000 mg/L.A biogas production of 0.35–0.4 L/gVS in and a COD conversion of 68% were achieved when TAN concentration

2023/12/15/ · The fermentation technology in the cylinder is temperature-controlled, and the structure of the organic fertilizer fermentation tank is horizontal. Vertical Fermentation Tank: Based on the nature of the solid phase in the rapid fermentation tank of organic fertilizer, chicken manure fermentation can be divided into two .

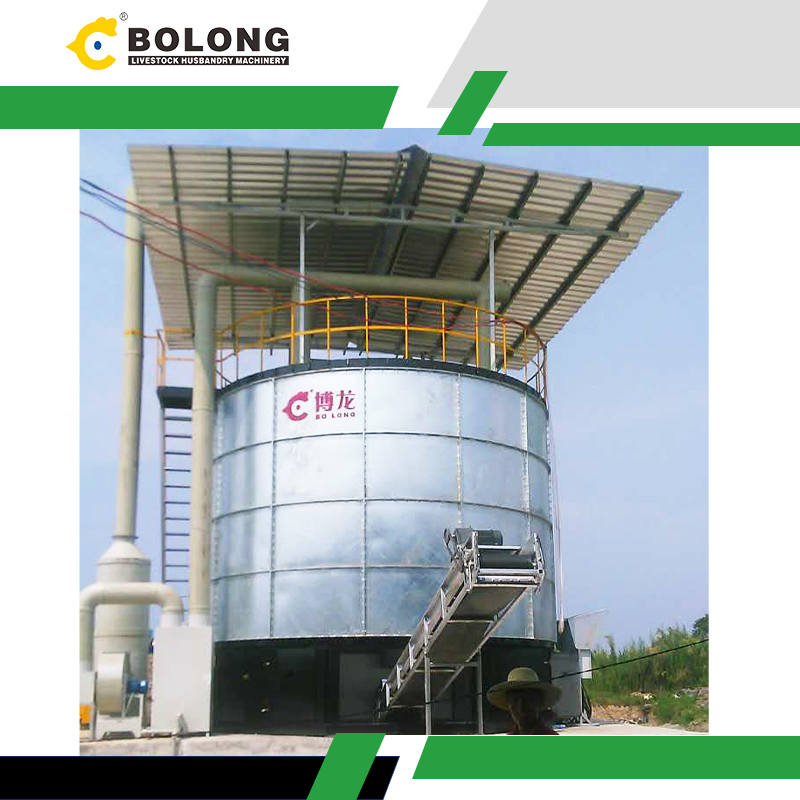

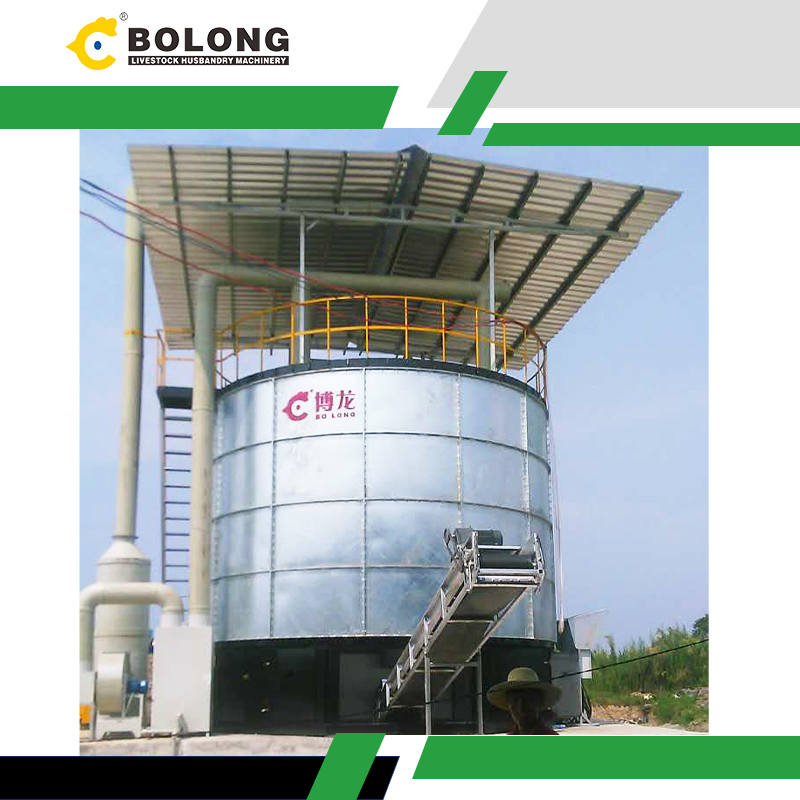

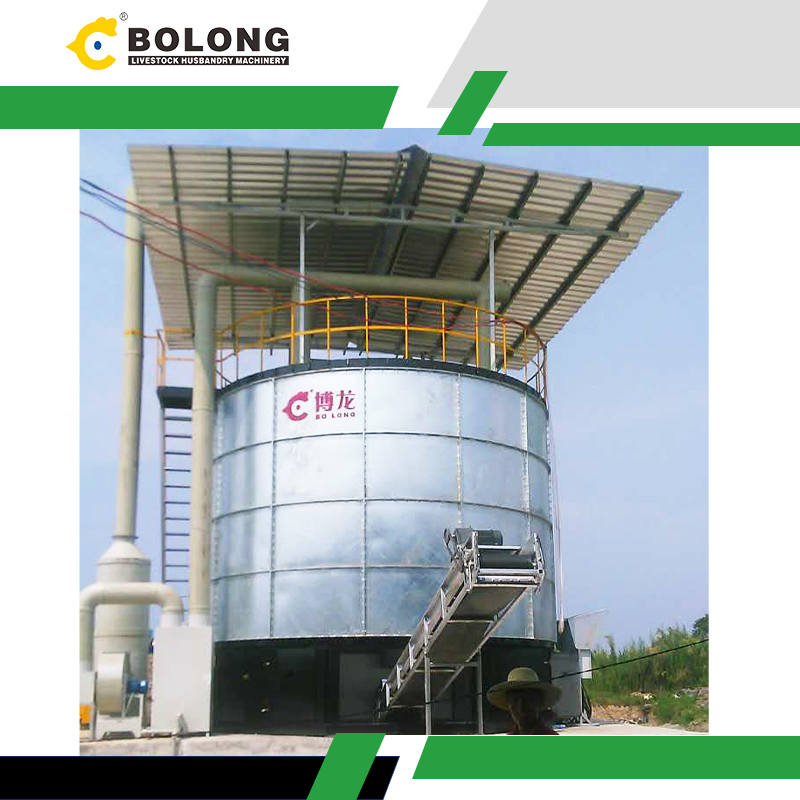

There are four treatment procedure of the organic fertilizer fermentation tank. Firstly,automatically feeding.Then,you can make material get perfect stage through high-temperature fermentation. After that,material is discharged from your fermenter. Finally,you can put these fermented material into storage. organic tertilizer production tank.

The first option——To make chicken manure waste compost. Two types of high-efficiency composting equipment: Organic Fertilizer Fermentation Tank and Compost Turner. Organic Fertilizer Fermentation Tank:. Output: 3~4.5 m³/day. Power Supply: 380V50Hz. Treatment capacity: 7~10 m³/day.

2023/2/18/ · Therefore, if poultry manure is fermented in an air-tight bag in an anaerobic condition with a fermentation mixture of PM (90%) and molasses (10%) inoculating 10% IMO at least for 7 days, it can

Chicken manure fermentation tank To meet the customers' over-expected satisfaction , we have our strong team to provide our best overall service which includes marketing, sales, designing, production, quality controlling, packing, warehousing and logistics for Chicken manure fermentation tank, Poultry Cage System , Poultry Layer Chicken Cage

The Fermentation System has a 25-70m long, 1.3m or 1.5m deep and 8.3m wide tank with a central bulkhead and a circular shape at both ends. It has a rotating agitator that moves on top of it. The agitator goes on the right side (A side), stirring the chicken manure. When it reaches the end of the tank, it moves to the left side (B side) and

2022/8/26/ · 【How to deal with chicken manure in chicken farms? 】In addition to the traditional fermentation method, the new type of chicken manure fermentation tank is a good choice. With the closed

Organic manure vertical fermentation tank designed by FPC company with 100-200m³ processing capacity. Manure fermentaion finished in 7days. Compost Shredder For Sale; Cow Dung Dryer Machine Cost; Cow Dung Dewatering Machine; ... Sri Lankan 10t/h Chicken Manure Fertilizer Production Line;

Organic Fertilizer Production Poultry Manure Compost Tanks Fermentation Equipment, Find Details and Price about Fermentation Tank Fermentation Tank for Sale from Organic Fertilizer Production Poultry Manure Compost Tanks Fermentation Equipment - Henan Tongda Heavy Industry Science And Technology Co., Ltd. Pre-sale Service: 1.Offering ...

2021/11/12/ · Outfit of intelligent solar chicken manure fermentation system. 2.2. Structure Design and Construction of Fermentation Tank In this study the fermentation tank system was built on the outdoor ground, and a shelter was installed to avoid serious disturbance or rainwater accumulation. The structure of the fermentation tank includes

2023/5/2/ · Anaerobic digestion of animal manure results in the production of renewable energy (biogas) and nutrient-rich biofertilizer. A further benefit of the technology is decreased greenhouse gas emissions that otherwise occur during manure storage. Since animal manure makes anaerobic digestion cost-efficient and further advance the …