The first option——To make chicken manure waste compost. Two types of high-efficiency composting equipment: Organic Fertilizer Fermentation Tank and Compost Turner. Organic Fertilizer Fermentation Tank:. Output: 3~4.5 m³/day. Power Supply: 380V50Hz. Treatment capacity: 7~10 m³/day.

FPC vertical type manure fermentation tank is an advanced organic fertilizer production machine. It can complete organic waste crushing, mixing and fermentation automatically. What’s more, there will not odor produced during the organic manure fermentation process. And the waste water can be recycled.

2024/1/2/ · One hundred fifty tons of liquid manure was fermented in a liquid manure tank by an air ring blower at 0.03–0.045 m 3-air/min·m 3, and 14 t of solid manure was fermented in a solid manure

Aquaculture is a fast growing global food production industry playing an essential role in meeting the increasing demand for fish and seafood products that cannot be fulfilled via wild catch fisheries. 1 FAO 2 reported that global fish production in Optimize fermentation conditions: Fermentation is reported to influence by various factors ...

The Weight Proportion of manure and Auxiliary material is about 5 to 10 :1. Confirm the proportion, then could get good compost. 2. Put the raw materials in fermentation tank by Fork-lift truck, height at least 1meter. Spread the mixed leaven in materials evenly. 2.2.2 Fermentation steps. 1.

Horizontal fermentation tank structure: Firstly, the material to be fermented is fed into the fermentation tank through a belt conveyor from the feeding port. While feeding the material, the main motor is started, and the main shaft is driven by the motor reducer to start stirring.

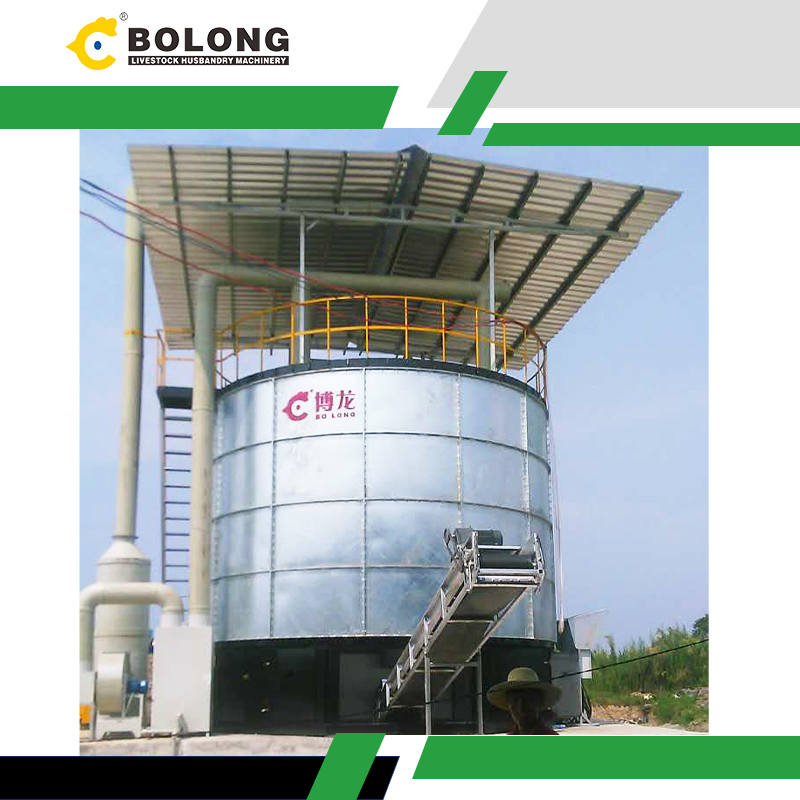

The first fermentation process in a manure fermentation tank will last about 7 days, after which the production of organic fertiliser can be carried out every day. Good Adaptability. Bolong fermentation tank, the inner wall is all made of 304 stainless steel, which is anti-corrosive and uses high-performance insulation materials, which is less

2023/12/15/ · Horizontal Fermentation Tank: The process begins by uniformly mixing collected manure in the fertilizer box and then pumping it into a dry-wet separation pretreatment machine within the system. After pretreatment, the manure enters the main machine for solid-liquid separation. Dry matter from the fermentation bucket continuously

There are four treatment procedure of the organic fertilizer fermentation tank. Firstly,automatically feeding.Then,you can make material get perfect stage through high-temperature fermentation. After that,material is discharged from your fermenter. Finally,you can put these fermented material into storage. organic tertilizer production tank.

The moisture content should be controlled at 50%-75% during fermentation. High Temperature. 50-70℃ is the ideal temperature for aerobic reproduction. Our fully automatic composting machine can keep the temperature between 50℃-65℃ and last about 5 days. Abundance Oxygen.

China Fermentation Tank Manure Treatment Equipment wholesale - Select 2024 high quality Fermentation Tank Manure Treatment Equipment products in best price from certified Chinese Industrial Equipment manufacturers, Equipment Component suppliers, wholesalers and factory on Made-in-China.com Factory Direct Sales of Clean Waste …